Following the important acquisition of the Ipeg Group with its Conair, Thermal Care and Pelletron brands, the PiovanGroup has further consolidated its world leadership in systems for the automation of plastics processing.

With Penta, the Group is also present in the processing of food powders and creams, providing systems for the handling and processing of raw materials, with very important growth prospects.

In addition to the Plastics and Food sectors, we have experience in the treatment of process fluids, offering solutions for industrial refrigeration and thermoregulation.

Passion, tenacity and constant determination in pursuing the company philosophy have rewarded us, leading us to be a multinational organisation with 14 production plants and 40+ service and sales companies around the world, employing a total of more than 1,800 people.

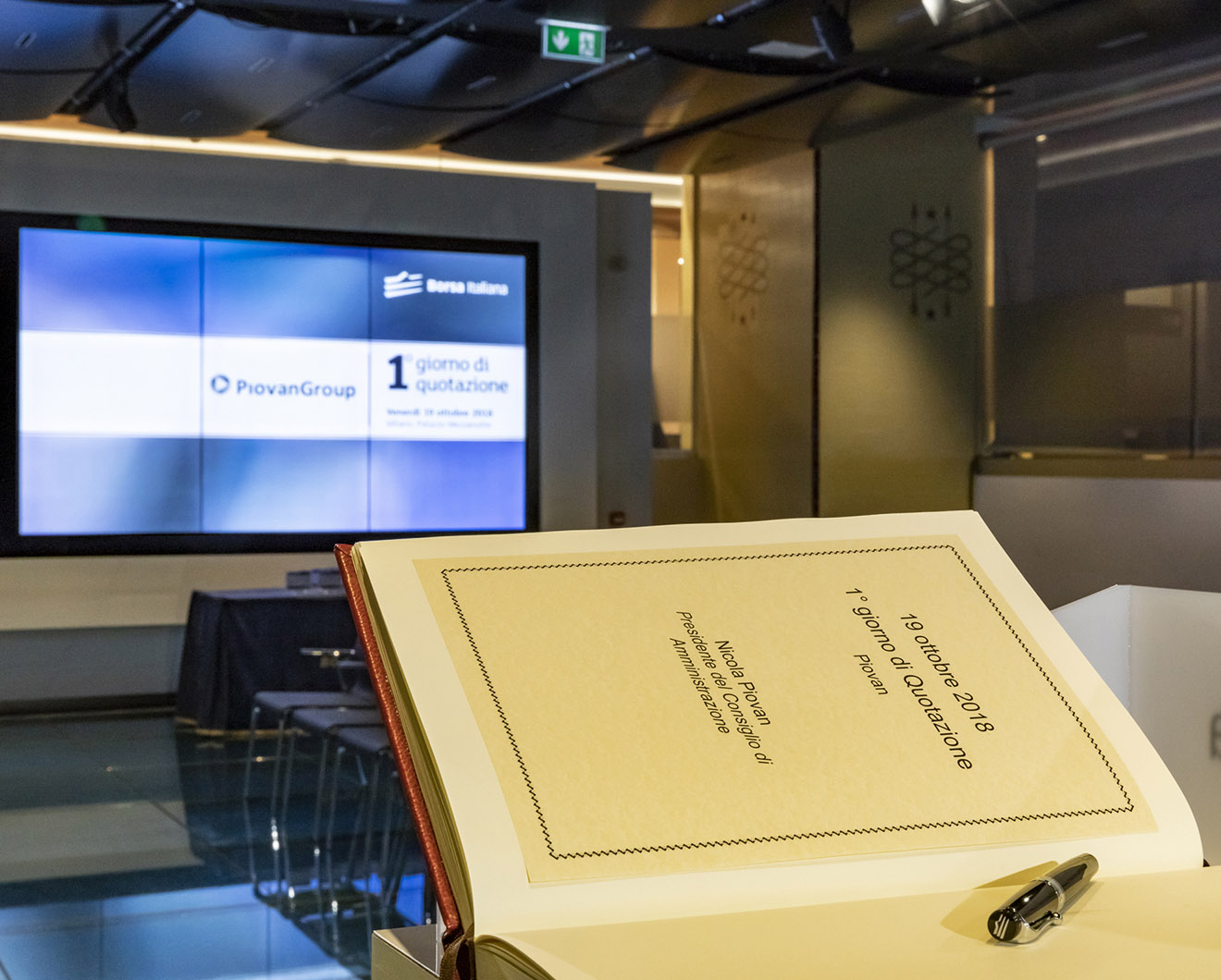

Compared to 2018, the year of listing on the Star segment of the Italian Stock Exchange, the PiovanGroup has more than doubled its size, anticipating the business plan communicated at the time of listing. But what makes us proud more than anything else is that all this has been done consistently with our values.

Customers, People, Innovation. These are the pillars of our philosophy that have led us to grow along a path that began more than fifty years ago, pursuing our development goals with honesty, integrity and transparency. Principles to which we have been faithful for three generations.

It is with this clear strategy that we will face the stimulating challenges that await us, convinced that the growth of the PiovanGroup must always be the result of responsible choices, balance, reliability and positive working environments, oriented towards value for the customer and for the social contexts in which we operate.

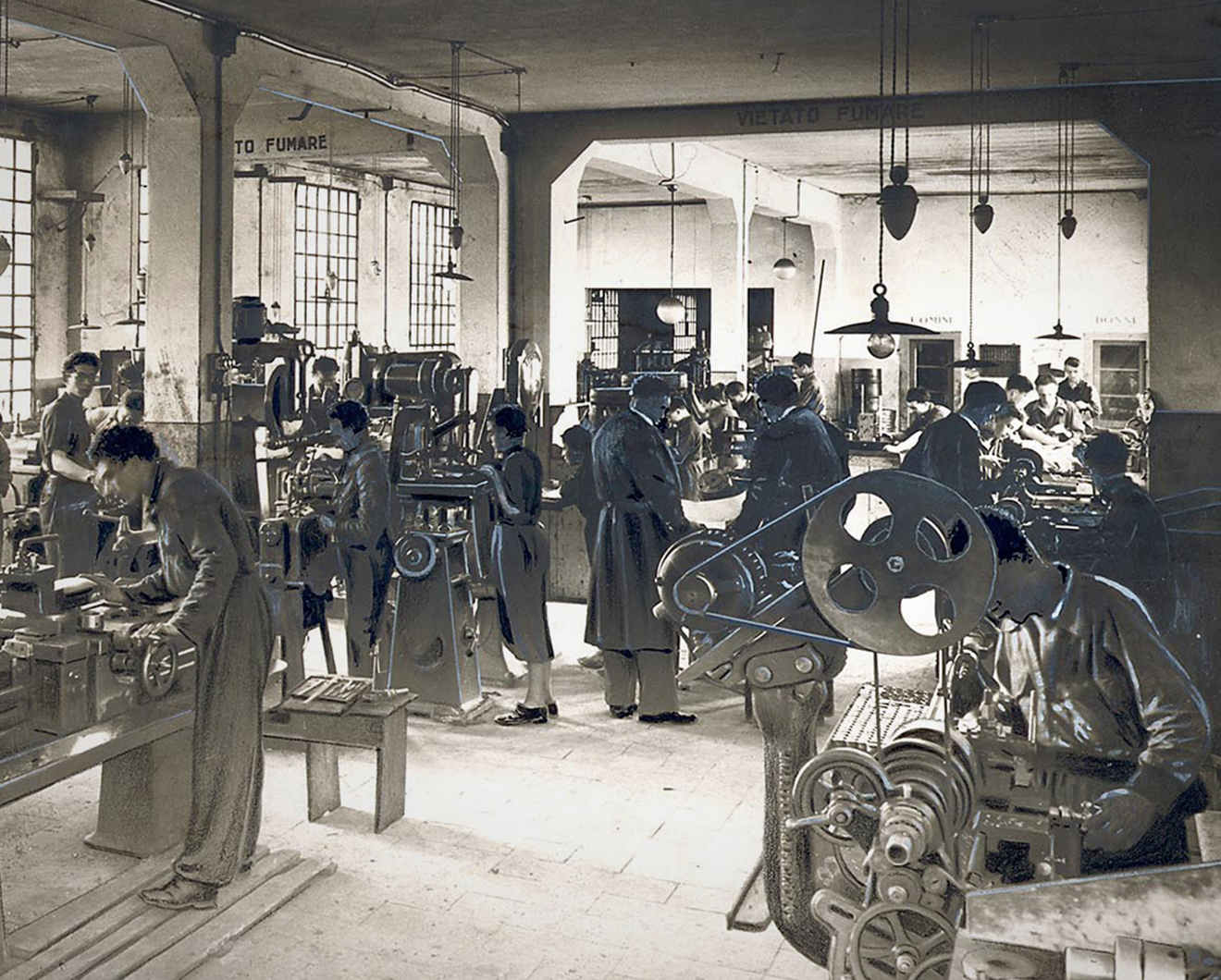

1934

1950s

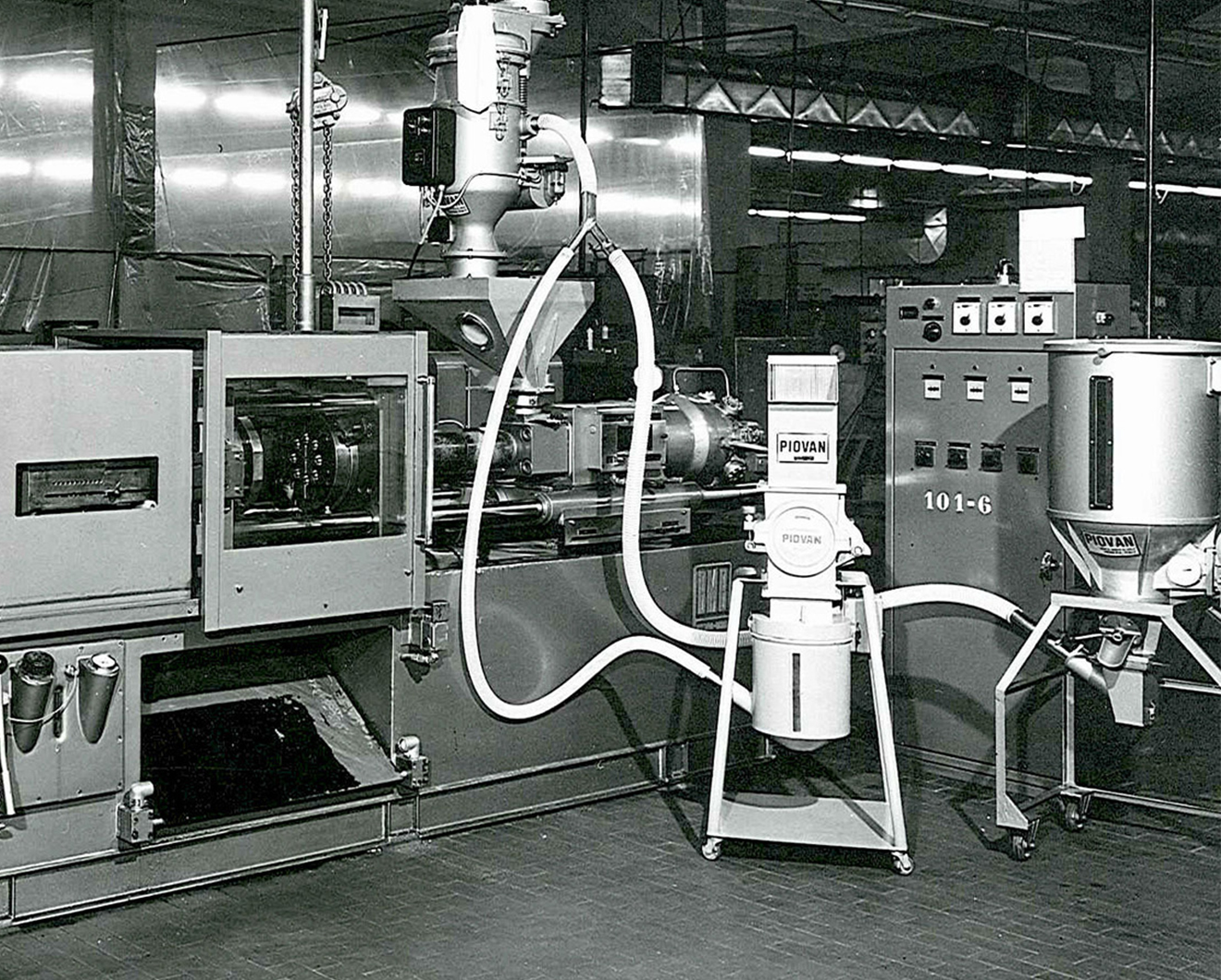

1960s

1970s

1990s